Context

Our bodies have evolved to sleep during the night and wake-up as down starts to break. In the winter months, with sunrise happening later, most people will have to resort to alarm clocks ringing while it is still dark outside. This is a rough way to be awakened and can be depressing too. A wake-up lamp provides a more “natural” wake-up routine, simulating a sunrise by gradually increasing in brightness until full brightness, which coincides with the alarm time. This hack was inspired by a Philips product.

Hardware

The wake-up light requires a dimmable light source; being able to control the color temperature is an added bonus, but not mandatory. For this project I’m using a smart LED bulb I had a few units lying around, the Sonoff B1 from Itead.

Replacing the B1 Firmware

To control the smart bulb from Home Assistant we’ll be flashing it with ESPHome. A couple notes: it is possible to integrate the LED bulb with Home Assistant keeping the original firmware unchanged; it is also possible to use Tasmota as the final firmware or as an intermediate in order to perform the first Over the Air (OTA) flashing, and then move to ESPHome. For this project I’ve decided to go straight to ESPHome and use it as the final firmware, same as other Sonoff devices I’ve modified earlier.

Flashing with ESPHome

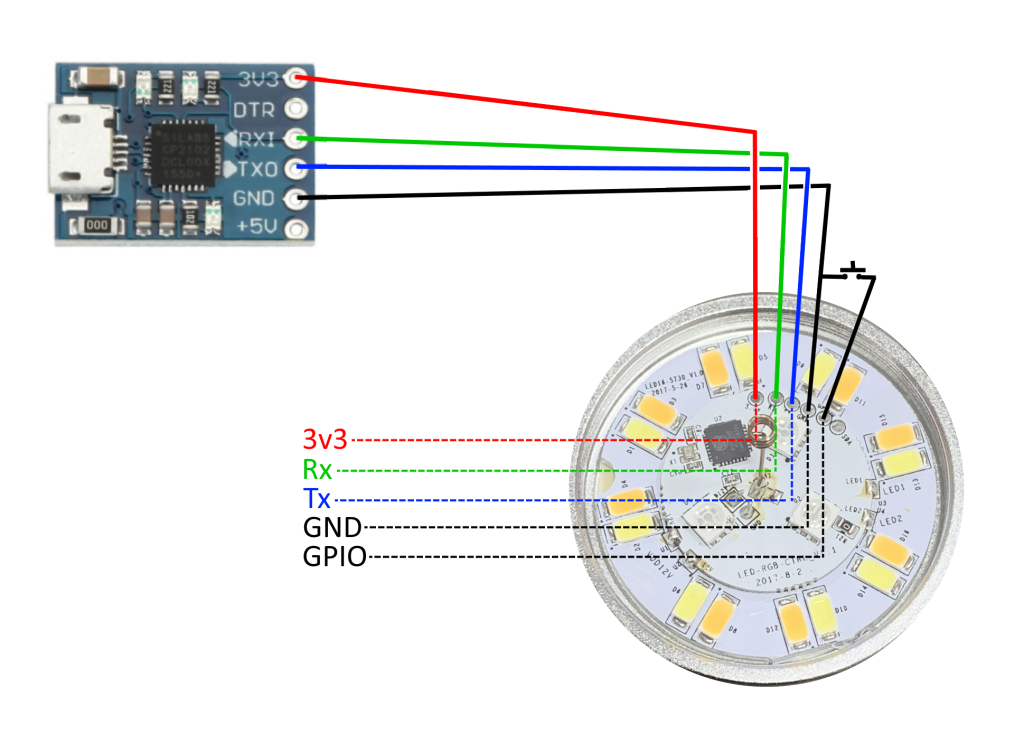

The Sonoff B1 does not have header pins or thru vias to simplify the serial connection required for the first re-flashing; you’ll have to either solder pins for a temporary connection, or have a steady hand for holding a pin header bar against the pads for the duration of the upload. The schema for the serial connection is depicted below:

- Note that the GPIO0 pin must be held to ground while booting in order to put the device in flash mode. It can be released after flashing is complete to allow a normal boot (and inspecting the logs)

- While flashing the bulb must not be connected to mains power; it should be powered entirely by the 3v3 line from the UART adapter

- Ensure that 3v3 power is used; feeding 5v to this device will damage it

More information about this procedure can be seen here: https://tasmota.github.io/docs/devices/Sonoff-B1/#serial-flashing

ESPHome Firmware

The following is a minimal ESPHome configuration for the Sonoff B1. For the full config used in this project refer to github here: https://github.com/heckler/esphome-device-configs/blob/master/wakeup_light_01r.yaml

esphome:

name: wakeup_light_01r

platform: ESP8266

board: esp01_1m

arduino_version: 2.4.2

wifi:

networks:

- ssid: !secret wifi_ssid_1

password: !secret wifi_password_1

ota:

safe_mode: True

password: !secret ota_password

api:

logger:

level: DEBUG

my9231:

data_pin: GPIO12

clock_pin: GPIO14

num_channels: 6

num_chips: 2

bit_depth: 8

output:

- platform: my9231

id: output_blue

channel: 0

- platform: my9231

id: output_red

channel: 1

- platform: my9231

id: output_green

channel: 2

- platform: my9231

id: output_warm_white

channel: 4

- platform: my9231

id: output_cold_white

channel: 5

light:

- platform: rgbww

name: wakeup_light_01r

red: output_red

green: output_green

blue: output_blue

cold_white: output_cold_white

warm_white: output_warm_white

cold_white_color_temperature: 6500 K

warm_white_color_temperature: 2800 K

With the config above it is already possible to connect the device to Home Assistant and have full control of its different LEDs – the B1 have independent cool and warm white LEDs, as well as a set of low power RGB LEDs

The next post(s) will deal with the automation scripts in Home Assistant to create the desired sunrise simulation tied to a specific alarm time.